Gears and chain transmission

Summary

How to transfer rotational energy from one wheel to another? This simulation illustrates two possibilities:

- Gears

- Chain transmission

Gears are a mechanical system made of two discs with teeth that mesh smoothly into one another. The two gears are in contact at all times as a tooth of the driver gear pushes a tooth of the driven gear. The driver gear transfers its rotational movements to the driven gear, but the gears turn in opposite directions.

A chain transmission connects two gears that are not in contact. Unlike a belt, a chain is made of links allowing a smooth transmission without sliding. The gears turn in the same direction.

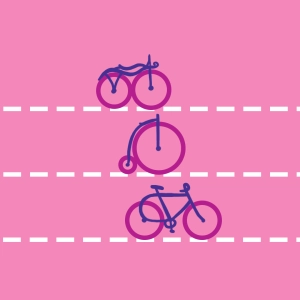

In both cases, the speed of rotation of the driven gear depends on the dimensions of both gears.

Learning objectives

- To analyse and compare how different technologies involving the transfer of movement work.

- To know how to relate the demand and the technology.

Learn more

The transmission ratio (R) of the mechanical system is equal to the ratio between the output values (speed of the driven gear) and input values (speed of the driver gear). R is also defined by:

R = Number of turns of the driven gear / Number of turns of the driver gear

- If the number of teeth of the driven gear is smaller than the number of teeth of the driver gear, then the driven gear makes more than one turn while the driver gear completes only one turn. The driven gear turns faster than the driver gear: R > 1.

- If the number of teeth of the driven gear is greater than the number of teeth of the driver gear, then the driven gear makes less than one turn while the driver gear completes only one turn. The driven gear turns slower than the driver gear: R < 1.

- If the number of teeth of the driven gear is equal to the number of teeth of the driver gear, then the driven gear makes the same number of turns as the driver gear. Both gears turn at the same speed: R = 1.